HighRes - The High resolution scanner project

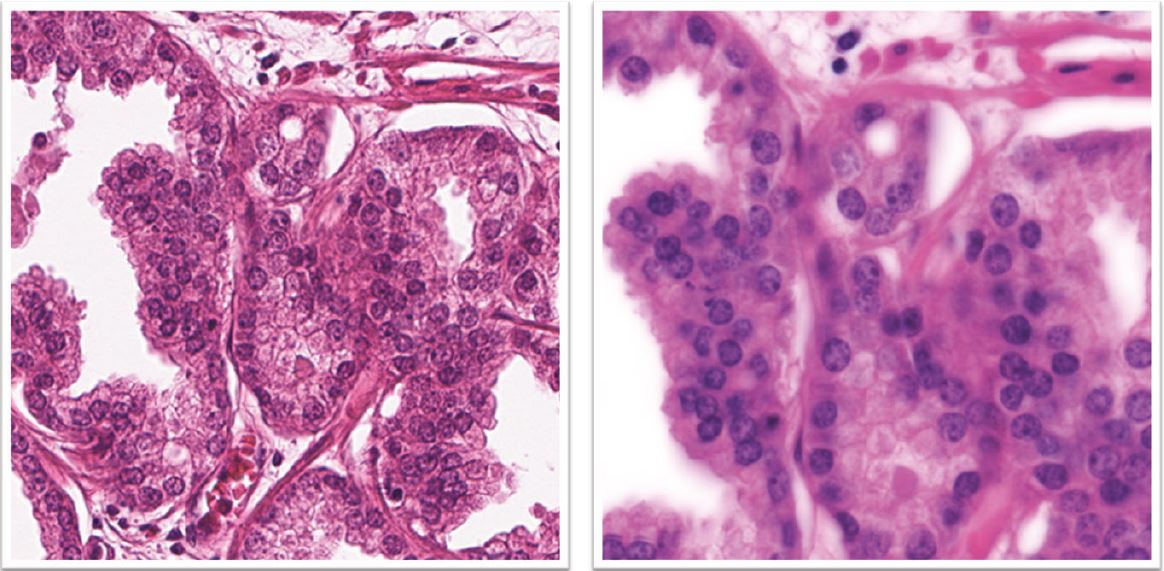

Commercially available scanners are designed for speed and image viewing, not for image analysis. Hence, the image resolution is inferior to standard light microscopy and with extremely limited flexibility to control or alter the light. The High-Res project aims to create a flexible and autonomous system that will push the boundaries of histopathology imaging.

By identifying and solving issues in this domain, we aim to move away from proprietary platforms and formats, digitise larger datasets, and free up labour costs through extensive automation. Generated images will be optimised for digital analyses, not for visual inspection by humans.

We aim to test the benefits of novel microscopy paradigms like hyperspectral and ptychographic imaging while improving the old methods’ colour fidelity and focus. We need a flexible system that can alter both light and resolution and adapt to the requirement of each project. We need to control all aspects of our imaging and add new functionality as our research progresses. The integration of the High-Res with an in-house ICGI laboratory information system will reduce errors and enable more rapid testing of novel methods for cancer prognostication.

The High-Res project has six overlapping stages: System Design, Parts Sourcing, Parts Control, System Control, Test & Validation, and Description & Integration.

The system design (I) and parts sourcing (II) phases are approaching completion. In the system design phase (I), the project has outlined priorities that shape the scanner design. A prototype model has been created in CAD software to identify parts for in-house production or external purchase. High-Res has carefully vetted the suppliers to future-proof the solution and minimise its cost. These conversations have allowed the project to move from a microscope-based prototyping platform to an entirely new scanning system in Parts Sourcing (II) phase. Most components in the bill of parts are already in store, including camera and motorised axes, except some that require testing before purchase. The Parts Control (III) phase will involve several ICGI developers without prior knowledge of the hardware domain to solve different programming tasks. To simplify software development, High-Res now has a common hardware interaction platform that brings an interface to scanner components and optical parameters like camera pixel size and magnification. With this platform, the parts control code wraps into independent modules that can evolve without affecting the rest of the system. The ICGI application development team is already involved in High-Res-related tasks. In essence, discussions about a built-in CNN focus evaluator and an efficient image stitching algorithm are underway. The developers are conducting tests on image data from the prototyping platform.

High-Res will further examine the choice of camera and test sCMOS technology. An sCMOS-based camera will give ICGI the benefit of alleviating our dependency on soon-obsolete CCD sensors. The first mode to be tested for the scanner is the single slide scanning. To do this, laboratory personnel must have a way of initiating the scans and storing data. For this, a user interface will be developed as a part of the System Control (IV) project phase after the single slide scan mode will work on the autoloading component in parallel with the test & validation phase (V) of the project. In the test & validation (V) phase, scanner colour profiles and focus metrics will be standardised. Also, High-Res will begin scanning subsets of large project materials to compare system performance to the commercial systems. The comparison will most likely involve Histotyping, nucleotyping, stroma fraction, and mitotic index.

There will be enough data to decide whether the project has achieved its goals when the laboratory personnel scans whole materials with 1000+ samples. This work will start while the project team gets feedback and introduces necessary cosmetic changes without affecting the image quality. Here the autoloading system is a crucial dependency.

High-Res will complete system documentation that describes how to operate and keep the system at its optimal performance. The documentation will be subject to feedback from the lab technicians.

In the prototype phase, the main challenge of High-Res has been the immense increase in data throughput compared to off-the-shelf systems. In a standard digital pathology scanner, the numerical aperture will seldom exceed 0.8. The number of pixels needed to adequately capture the detail level available at this numerical aperture is moderate. High-Res is designed to operate close to the limit of resolving capability of a brightfield microscopy system at numerical aperture 1.4. This corresponds to a seven-fold increase in the necessary pixels according to the Nyquist-Shannon sampling theorem.

A dedicated action sequencing platform is developed to speed up the communication of components based on Xilinx FPGA. Postprocessing steps are outsourced into the high-performance cluster to reduce the image processing-related delay. For future scaling needs, we are creating a 12.5 GB/s bridge between the processing cluster and the instrument using the latest technology from GSense, Sony and Mellanox. Before this solution is ready, High-Res already displays an immense performance boost by transporting four times the number of pixels in three channels compared to the legacy nucleotyping systems. This equals a 12-fold increase in data throughput.

Imaging at this resolution has no benefit if the imaging camera introduces mosaicking artefacts after converting the colour camera sensor’s output. To alleviate this, we have extended High-Res with a multichromatic illuminator that offers an exact registration of the signal at the correct spatial locations. This illuminator offers the flexibility of white light illumination for projects that require fast acquisition.

The built-in tissue detection recognises 90% of haematoxylin-eosin-stained tissue areas with acceptable precision. This will serve as a temporary solution until a training set is ready for a CNN-based tissue detector. If this success rate endures the testing, it will provide the laboratory personnel with a true 1-click operation.

A focusing mechanism prototype is assembled to allow one-shot focusing. This allows evaluation of the sample surface in motion, as opposed to the traditional time-consuming assembly of focus stacks.

A passive vibration system is implemented, and an active vibration cancellation system is to be completed by the start of 2021. Motion systems are calibrated for the correct load to achieve the correct response to the payload.

A specimen handling system is outlined to provide the safe transport of slides even after oil immersion. This step brings us closer to the loading capability, allowing overnight batches in those cases when quality cannot be compromised for speed.

Full control of hardware components independent of 3rd party tools is achieved. High-Res is using either raw hardware interfaces or supplier’s SDK. This provides faster operation and reduces the number of licensing issues down the development line.

Prototypes of the following subsystems are already in use:

- High-Res-DYN

- High-Res-ACQ

- High-Res-MACRO

- High-Res-LIGHT

- High-Res-XY

- High-Res-Z

- High-Res-IRIS

- High-Res-POWER